Hydrocarbon Recovery

Environmental legislations are becoming increasingly restrictive disposal. This requirement becomes even more important in the cleaning of tanks, as the removal of tank sludge treatment is expensive and time consuming. Manual cleaning always implies a special attention to safety of operations.

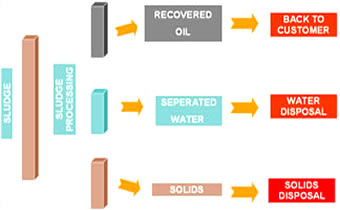

Our Recovery Process

The process is carried out in a closed loop system to avoid any spillage safety hazards during the process.

Deliverables

Where we can help

Tank Management Program

Tank Cleaning

Fine Cleaning

The Clean out openings would be opened and the tank interior is washed with thoroughly using high pressure jetting or proprietary surfactant mixtures under moderate pressure. The process leaves tanks clean, gas-free and ready for inspection or hot work permitting.

Magnetic Flux Leakage (MFL) Tank Inspection

Magnetic Flux Leakage (MFL) Tank Inspection is an advanced magnetic method of NDT used for tank inspection. At areas where there is corrosion or missing metal, the magnetic field "leaks" from the steel. In an MFL tool, a magnetic detector is placed between the poles of the magnet to detect the leakage field. Analysts interpret the chart recording of the leakage field to identify damaged areas and to estimate the depth of metal loss.

Handscan System

The Handscan system is designed to compliment the MFL 2000 and FloormapVS2i floor scanners. The latest generation of permanent magnets allows localized magnetic saturation of the floor area under test. As the scanner is moved across the test area signals from the corrosion are detailed by the hall effect sensors.