Pipe Line Fittings :- Overview

Pipe Line Fittings are an outstanding choice for water, sewage, chemical, and fertilizer transfer, as well as many industrial applications. The Hot Tap Pipe Line Fittings are full branch split tees designed for equipment tie-ins, lateral connections, and line extensions with permanent full bore valves without shutdown. Our full-encirclement Hot Tap & Line Stop Pipe Line Fittings are available in ANSI 150, 300, 600, and 900 Series, ranging from 0.5” through 60” sizes. Split sleeve Pipe Line Fittings are also manufactured with side outlets featuring a weld neck flange for hot tapping.

The Line Stop Fitting are designed for pipeline relocations, lateral connections, line extensions,equipment tie-ins, line stop operations all without shutdown.

Line Stop Fittings are compatible with specific tapping and plugging equipment and are designed to carry the extra loads imposed during hot tapping and line stopping operations. All fittings can be designed to ASME/ANSI B31.8 (Gas Pipelines); B31.4 (Liquid Pipelines); B31.3 (Chemical Plants & Refineries); B31.1 (Power Plants)

Products

- Hot Tap Fittings

- Line Stop Fittings

- Angle Hot Tap Fittings

- Equalization Fittings

- Special Bottom out Fittings

- Special Four Piece Fittings

- Special Y-Type Fittings

- Gas Bag Fittings

- 3-Way Fittings

Description

- Design Code : ASME B31.3 / 31.4 / 31.8 and Any other as per customer’s requirement

- Size : Diameter - 1/2” to 56”

- Class : 150#, 300# & 600#

- Temperature : -46̊ C to +300̊ C

- MOC : Carbon Steel

- Type : Extruded / Fabricated / Mechanical Fittings

- Certification Type : EN-10204-3.1 & 3.2

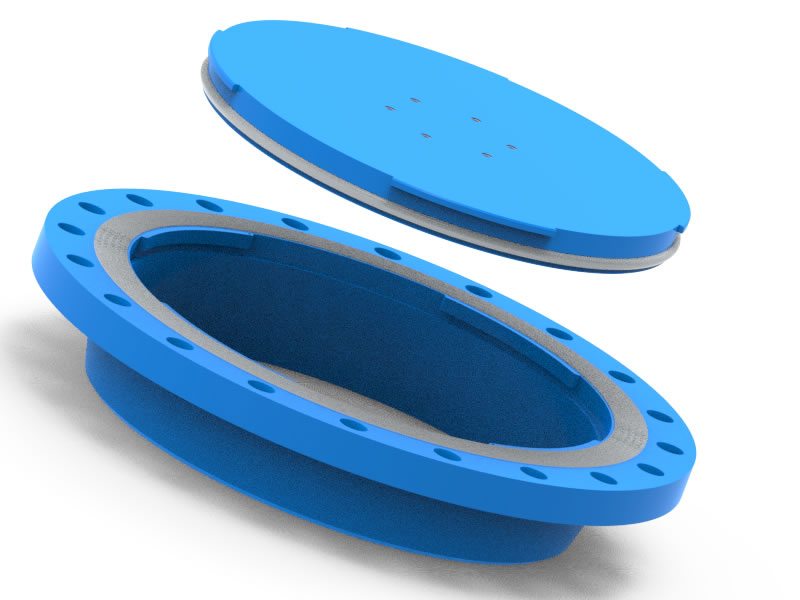

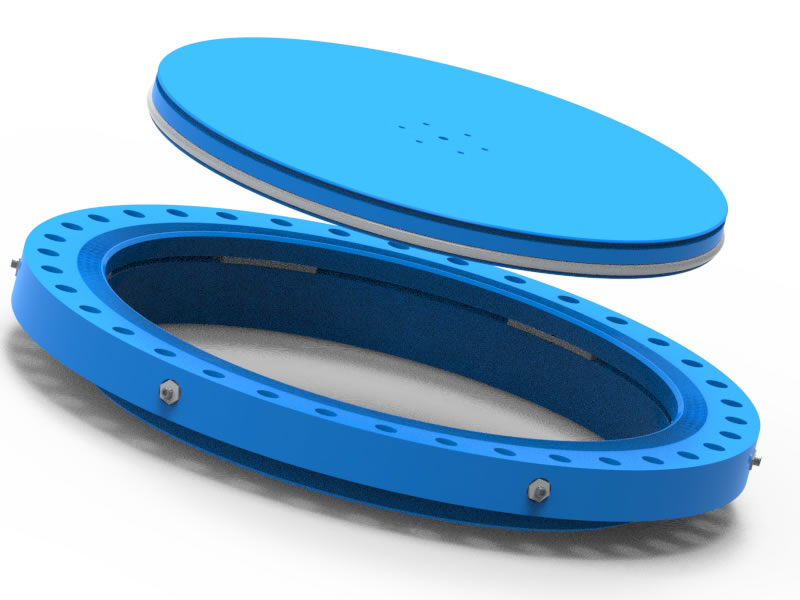

ConTiTe Completion Flanges

Three types, i.e. – pin type, segment type and cam type

Features of Pipe Line Fittings

- Versatility: Pipe Line Fittings are suitable for various applications, including water, sewage, chemical, and fertilizer transfer, as well as numerous industrial uses.

- Leak-Proof Connections: They ensure secure and reliable joints, reducing the risk of leaks even under high-pressure or high-temperature conditions.

- Durability: Constructed from robust materials, Pipe Line Fittings can withstand harsh environments, including corrosive substances and extreme temperatures.

- Ease of Installation: Designed for quick and efficient installation, they save time and labor costs during pipeline assembly or maintenance.

- Minimized Downtime: Advanced fittings like Hot Tap Fittings allow for maintenance or modifications without shutting down the pipeline, ensuring continuous operations.